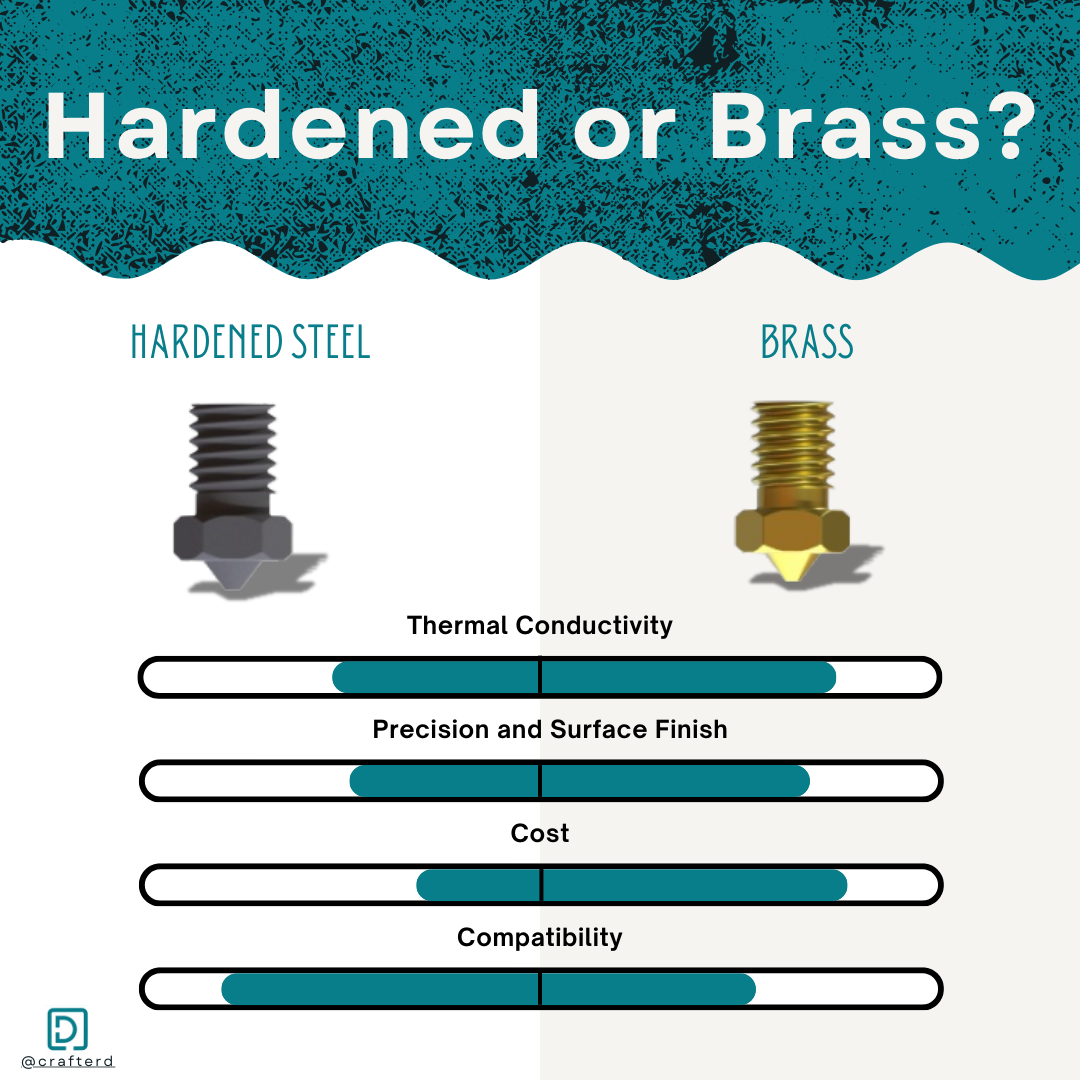

Choosing the right nozzle material is crucial for the quality, durability, and versatility of your 3D prints. Brass and hardened steel are two popular options for 3D printing nozzles. This article compares brass and hardened steel nozzles to help you make the best choice for your 3D printing needs.

1. Brass Nozzles for 3D Printing

Thermal Conductivity:

- Advantage: Brass nozzles have excellent thermal conductivity. This means they heat up quickly and maintain a consistent temperature, ensuring reliable filament extrusion. Brass nozzles are perfect for high-quality prints with standard filaments like PLA, ABS, and PETG.

- Disadvantage: Brass nozzles cool down quickly, which may not be ideal for filaments that need sustained high temperatures.

Precision and Surface Finish:

- Advantage: Brass nozzles provide precise and smooth extrusion, resulting in high-quality surface finishes. They are easy to machine, ensuring a smooth interior that enhances print quality.

- Disadvantage: Brass is a softer metal and wears out faster, especially with abrasive filaments, leading to reduced print quality over time.

Durability:

- Disadvantage: Brass nozzles wear out quickly when used with abrasive filaments like carbon fiber or metal-filled filaments. Grooves and ridges can form, closing off the nozzle hole or increasing its diameter.

Cost:

- Advantage: Brass nozzles are affordable and widely available, making them a cost-effective choice for general 3D printing needs. Their low cost and easy availability make them an economical option.

Compatibility:

- Advantage: Brass nozzles are suitable for non-abrasive filaments such as PLA, ABS, and PETG. They are the best choice for general-purpose 3D printing.

- Disadvantage: Brass nozzles are not suitable for highly abrasive filaments, which can cause rapid wear.

Genuine E3D Brass Nozzle Triple Pack 0.4mm, 0.6mm for V6 HotEnd 3D Printer

Genuine E3D Brass Nozzle Triple Pack 0.4mm, 0.6mm for V6 HotEnd 3D Printer

2. Hardened Steel Nozzles for 3D Printing

Durability:

- Advantage: Hardened steel nozzles are extremely durable and resistant to wear and tear, making them ideal for printing abrasive filaments. They can last significantly longer than brass nozzles, even with heavy use.

- Disadvantage: Hardened steel is harder to machine, which can result in a less smooth interior compared to brass nozzles.

Thermal Conductivity:

- Disadvantage: Hardened steel has lower thermal conductivity than brass. This means it heats up and cools down more slowly, potentially affecting print speed and consistency.

- Advantage: The slower cooling rate can be beneficial for materials requiring consistent high temperatures.

Precision and Surface Finish:

- Neutral: Hardened steel nozzles might not achieve the same smooth extrusion as brass due to their lower thermal conductivity. However, the impact on print quality is often minimal.

Cost:

- Disadvantage: Hardened steel nozzles are more expensive than brass nozzles. However, their longer lifespan can justify the higher initial cost, especially for frequent use with abrasive filaments.

Compatibility:

- Advantage: Hardened steel nozzles are suitable for a wide range of filaments, including highly abrasive ones like carbon fiber, metal-filled, and glow-in-the-dark filaments. They are versatile and durable for advanced 3D printing applications.

- Disadvantage: Adjustments to printing settings may be necessary to compensate for lower thermal conductivity.

E3D V6 Nozzle X 0,4 mm – 1,75 mm – 1 pcs

E3D V6 Nozzle X 0,4 mm – 1,75 mm – 1 pcs

General-Purpose Printing:

- Recommendation: Brass nozzles are ideal for standard filaments like PLA, ABS, and PETG. Their excellent thermal conductivity and affordability make them perfect for most 3D printing projects.

Abrasive Filaments:

- Recommendation: Hardened steel nozzles are best for printing abrasive filaments. Their superior durability and wear resistance make them suitable for filaments with abrasive additives like carbon fiber, metal particles, and glass.

Special Applications:

- Stainless Steel Nozzles: For food-safe or medical-grade parts, stainless steel nozzles are a good option. They offer better wear resistance than brass but are less durable than hardened steel.

Conclusion

In conclusion, the choice between brass and hardened steel nozzles depends on your specific 3D printing needs. Brass nozzles offer excellent thermal conductivity and are cost-effective for general-purpose use. Hardened steel nozzles provide unmatched durability for printing with abrasive filaments.

For users printing mostly with standard, non-abrasive filaments, a high-quality brass nozzle is sufficient. However, for those frequently using abrasive materials, investing in a hardened steel nozzle will pay off in the long run, providing reliable performance and reducing the need for frequent replacements.

By understanding the properties and benefits of each nozzle material, you can ensure optimal performance and longevity for your 3D printing projects.