The world of 3D printing has changed the game in manufacturing. It lets us make real things from digital designs. Now, more people, from hobbyists to small businesses, are diving into this new tech.

3D printing, or additive manufacturing, started in 1986. But it really took off in the 1990s. This guide will help you get started with desktop 3D printing. We’ll cover the basics, from understanding the tech to making your first 3D-printed item.

Key Takeaways

- 3D printing allows the production of complex shapes using less material than traditional manufacturing techniques

- The history of 3D printing dates back to the 1970s, with major advancements occurring in the 1980s and 2000s

- Desktop 3D printers have become more affordable and accessible, enabling hobbyists and small businesses to explore this technology

- Various industries, including aerospace, healthcare, and manufacturing, are actively utilizing 3D printing for a wide range of applications

- Beginners can start with desktop 3D printing by understanding the basics, setting up their printer, and exploring 3D modeling software

Introduction to 3D Printing

What is 3D Printing?

3D printing, also known as additive manufacturing, creates objects by layering material, usually plastic. This is different from traditional methods that remove material to make objects. It has changed how we make models and prototypes, making it faster and more detailed.

History and Evolution of 3D Printing

The first steps in 3D printing were in the 1970s with early equipment and materials. But it wasn’t until the 1990s that it started to get more attention worldwide. In the 2000s, it became more popular, and in 2008, the first self-replicating 3D printer was made.

In the 2010s, making objects layer by layer became common. Around 2012, people saw how 3D printing could help the developing world.

There are many 3D printing technologies, like FDM, SLS, SLM, SLA, and DLP. FDM is widely used since 2009. SLS is great for quick prototypes and small batches. SLM melts metallic powders for printing, and SLA and DLP make detailed parts with smooth finishes.

The process starts with CAD files, often in STL format. STL files can be big because of many surfaces. AMF is another format used in 3D printing. A typical layer is about 100 micrometers thick.

Filament materials for FFF 3D printers include ABS, PLA, HIPS, TPU, ASA, and PETG. 3D printing has changed rapid prototyping, making product development faster. It’s used in aerospace, medical, and education, among other fields.

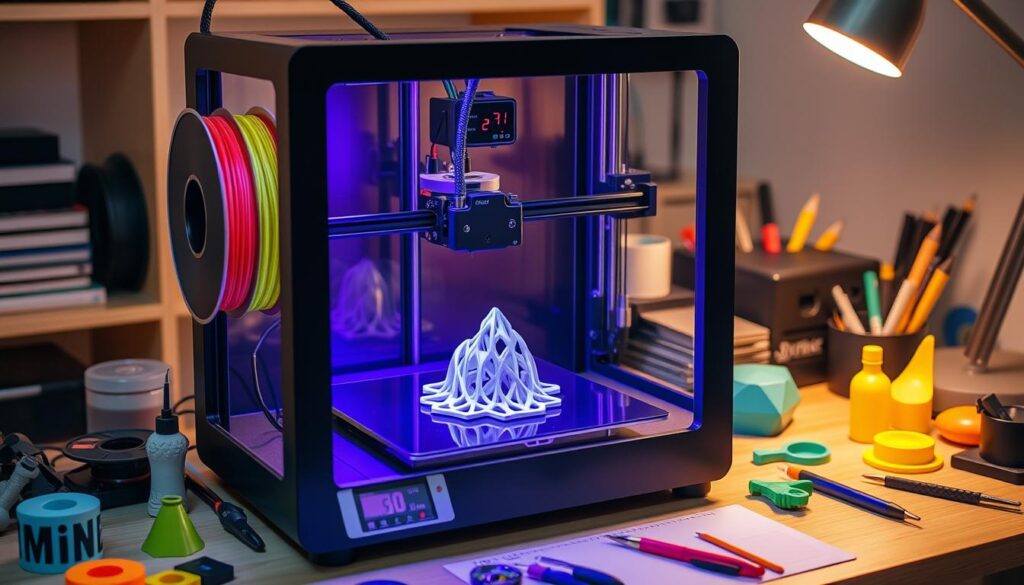

How Does 3D Printing Work?

Fused Deposition Modeling (FDM) is the most common method. It melts and lays down plastic filament layer by layer. Other methods include Selective Laser Sintering (SLS) and Stereolithography (SLA), which use lasers and light to create objects.

Starters use CAD software to make designs for 3D printing. PLA is a good choice for beginners because it’s affordable and easy to use. PET-G is also great for beginners, especially in industries that need strong and heat-resistant materials.

Every 3D printing method starts with a digital model. Then, it’s converted for the printer and built layer by layer. 3D printing helps many industries, like healthcare and fashion, by making things faster and more efficient.

3D printing is easy to learn, making it accessible to many. You need a 3D printer, filaments, and slicing software to get started.

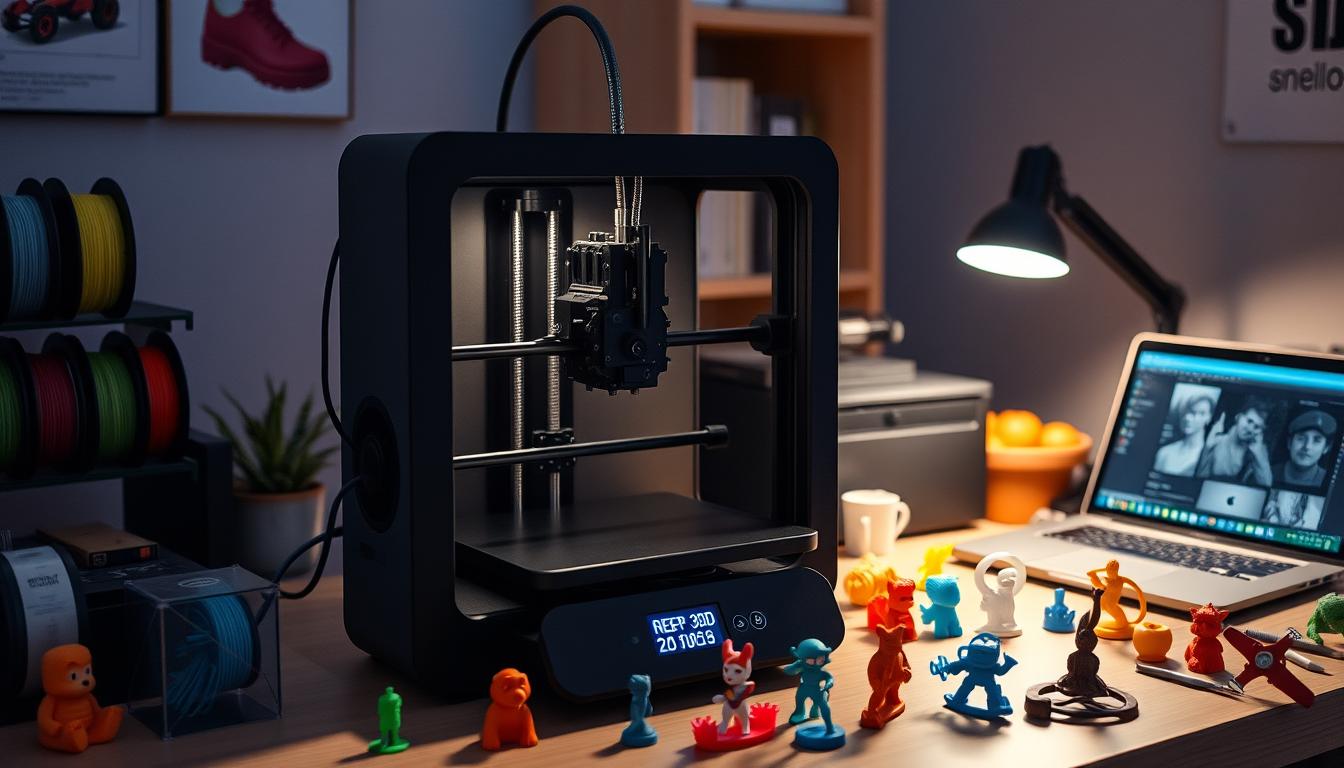

How to Start Desktop 3D Printing

Starting with desktop 3D printing is both exciting and rewarding. You’ll need a 3D printer, the right 3D printing materials, and slicing software. This software turns your digital 3D model into instructions for the printer.

Setting Up Your 3D Printer

Setting up your 3D printer is key. You must assemble it carefully, level the print bed, and calibrate the extruder. This makes sure your printer can create high-quality prints.

Understanding 3D Printing Materials

The 3D printing materials you choose affect your object’s properties. You might want flexibility, durability, or heat resistance. Filaments like PLA, ABS, PETG, TPU, and ASA have different qualities. It’s important to load and troubleshoot the filament correctly to avoid issues.

Learning about your 3D printer and the materials you can use opens up many possibilities. With patience and practice, you can create a wide range of objects. The possibilities are endless!

“The key to successful 3D printing is understanding the capabilities and limitations of your printer and the materials you’re working with.”

Whether you’re a hobbyist or a maker, desktop 3D printing is a great adventure. By following these steps, you’ll be able to bring your designs to life with precision.

3D Modeling and Slicing Software

To make a 3D printed object, start with a digital 3D model. You can design one using 3D modeling software or find one online. Tools like Tinkercad, SketchUp, and Blender are great for beginners. They offer different levels of complexity and features.

After getting your 3D model, use 3D printing software like Cura or PrusaSlicer. This software turns your digital file into something the 3D printer can print. You can also tweak settings like layer height and infill density to improve your print’s quality.

UltiMaker Cura 5.8.1 is the latest version of 3D printing software. It has over 400 settings for detailed control. It supports many file types, including STL, OBJ, and PNG. Plus, UltiMaker Cura Enterprise gets updates twice a year for stability and security.

UltiMaker also sends out a monthly newsletter with updates and resources. Their software is easy to use, even for beginners. The UltiMaker Marketplace offers materials and plugins for customizing your prints. It also works well with CAD plugins like SolidWorks.

Many of the 3D modeling software tools mentioned are free. Some, like Shapr3D, offer free versions with extra features for a fee. Most tools are for beginners, with only a few for advanced users.

In summary, using 3D modeling and printing software is key to creating 3D printed objects. Knowing what these tools can do helps you fully explore desktop 3D printing. This way, you can turn your ideas into real objects.

Practical Applications and Projects

3D Printing for Hobbyists

The world of 3D printing has opened up a realm of possibilities for hobbyists. Now, you can design and create personalized objects at home. The 3D printing community is thriving with innovative projects and inspiring ideas. From functional tools to whimsical decorations, the applications are endless.

Hobbyists can start with simple projects like a whistle that can produce a 118db sound. It’s perfect for camping or sporting events. They can also make durable carabiners that can hold up to 30kg of weight, or useful Mitre boxes for woodworking tasks. You can even create abstract planters for succulents and cacti, or a platform jack for painting models.

The 3D printing community offers a wealth of resources. There are online repositories of free 3D models and forums for troubleshooting and sharing tips. Enthusiasts can also attend local meetups for hands-on learning and collaboration. With affordable consumer-grade 3D printers available since 2009, hobbyists can bring their unique creations to life more easily than ever before.

From practical solutions like water-saving faucet attachments and cable organizers to whimsical designs like catapult toys and smartphone stands, the world of 3D printing offers endless opportunities for hobbyists to express their creativity and solve everyday problems. As the technology continues to evolve, the 3D printing community is sure to see even more inspiring and innovative projects emerge from the hands of passionate individuals.

| 3D Printing Project | Description | Time to Print | Difficulty Level |

|---|---|---|---|

| Whistle | A simple whistle that can produce a 118db sound, suitable for camping or sporting events | Approximately 1 hour | Easy |

| Carabiner | A durable carabiner that can withstand up to 30kg of weight | 30-60 minutes | Intermediate |

| Mitre Box | A useful tool for crafting and woodworking tasks | 1-2 hours | Intermediate |

| Abstract Planter | A modern and fresh design for succulents and cacti | 2-3 hours | Advanced |

“The growing 3D printing community provides a wealth of resources, including online repositories of free 3D models, forums for troubleshooting and sharing tips, and local meetups for hands-on learning and collaboration.”

Conclusion

Starting with desktop 3d printing is both rewarding and exciting. You’ll learn the basics of 3d printing, set up your desktop 3d printer, and get to know 3D modeling and slicing software. This lets you dive into the amazing world of 3D printing. 3D printing makes objects by adding layers of material until the object is complete, following five main steps.

If you’re into quick prototypes, making custom items, or just want a new hobby, desktop 3d printing is for you. This technology has been around since the 1980s and has grown a lot, with many industries using it today. With the right tools and practice, you can make your designs real and join the 3D printing community. It’s great for research and learning, offering fast and affordable ways to make prototypes, but it also has its challenges.

As you start your how to start desktop 3d printing adventure, remember the 3d printing basics you’ve learned. These will help you unlock the creative power of this technology. Be open to trying new things, experiment, and let your creativity run wild.

FAQ

What is 3D printing?

What is the history of 3D printing?

How does 3D printing work?

What do I need to start desktop 3D printing?

What are the common 3D printing materials?

What 3D modeling software can I use?

What are some practical applications of 3D printing?

What can I create with desktop 3D printing as a hobbyist?

Source Links

- How to 3D Print

- A Beginner’s Guide to 3D Printing

- How to 3D print? The Beginner’s Guide to 3D Printing

- What is 3D printing? How does a 3D printer work? Learn 3D printing

- 3d Print From ANYWHERE

- How to Succeed with Your First 3D Print | MatterHackers

- Beginners Guide to 3D Printing G-Code Commands

- Software for 3D Printing – 3D Modeling Software/Slicers/3D Printer Hosts

- UltiMaker Cura

- 67 Cool Things to 3D Print

- Practical Uses for 3D Printing in a Manufacturing Environment

- 3D Printing Basics

- What is 3D Printing? A complete guide on processes, applications, pros, and cons

- What is 3D printing? How do types of 3D printers work?

- What is 3D Printing?