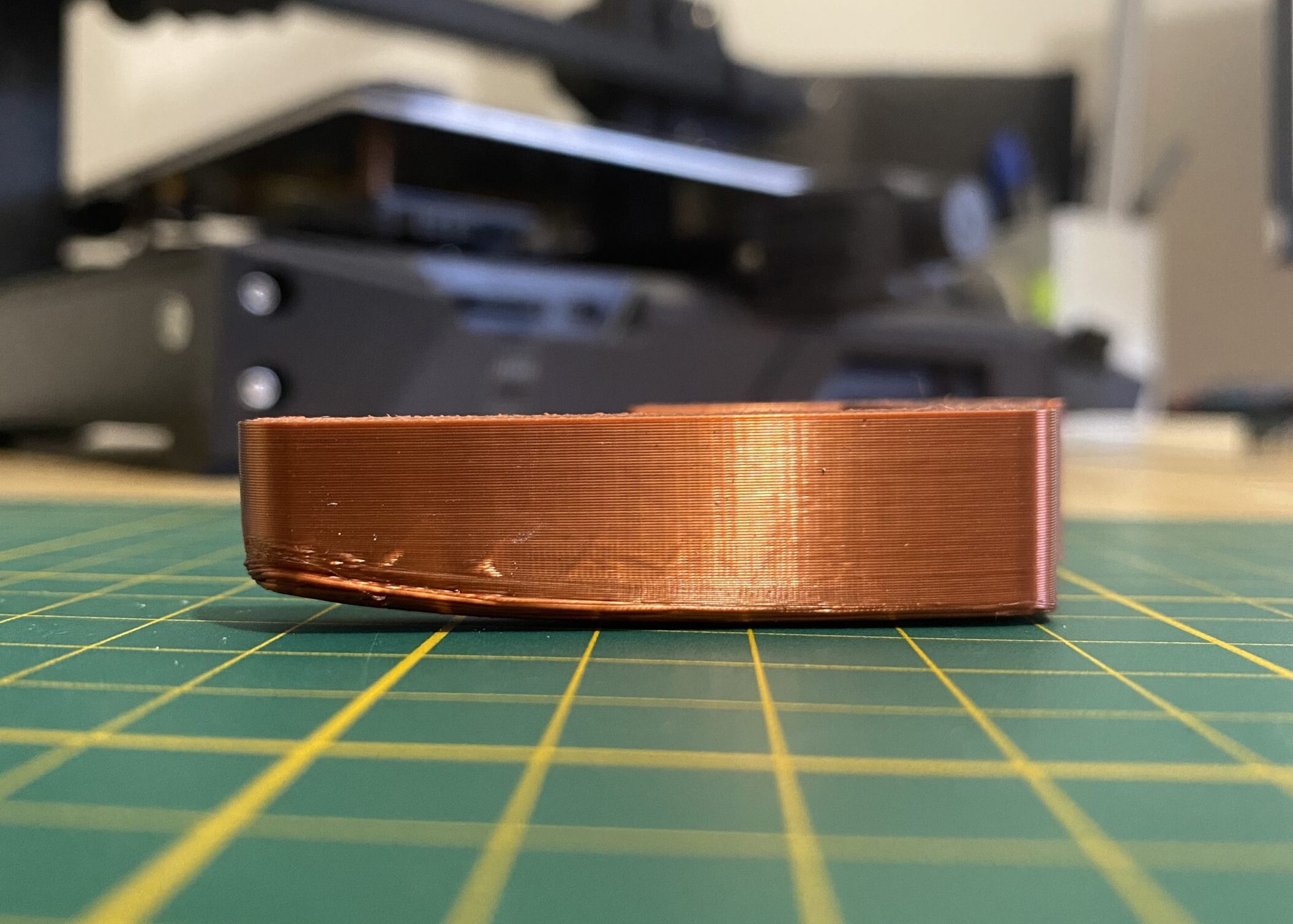

Warping is a common issue in 3D printing that can ruin your prints. It leads to deformation, affecting the part’s quality and usability. Understanding the causes and applying the right strategies will help you avoid warping and get accurate results.

Improve Bed and Layer Adhesion:

Poor adhesion between layers or the first layer and the print bed often causes warping. When stress builds up during printing, it can lift layers off the bed or cause delamination. Strong bed adhesion helps release this stress without deforming the part.

Ways to Improve Bed Adhesion:

-

- Use the Right Bed Surface and Coating: Different filaments need specific surfaces or coatings for better adhesion. For example, use a heated glass bed or apply glue stick or hairspray to enhance grip.

-

- Understand Layer Adhesion: Layer adhesion happens when polymer chains from one layer bond with those from the next. This occurs when both layers stay above their glass transition temperature (Tg).

Tips to Enhance Layer Adhesion:

-

- Increase Contact Time: Keep layers above Tg longer to allow better entanglement of polymer chains.

-

- Widen the Extrusion: A wider extrusion increases surface contact between layers, improving adhesion.

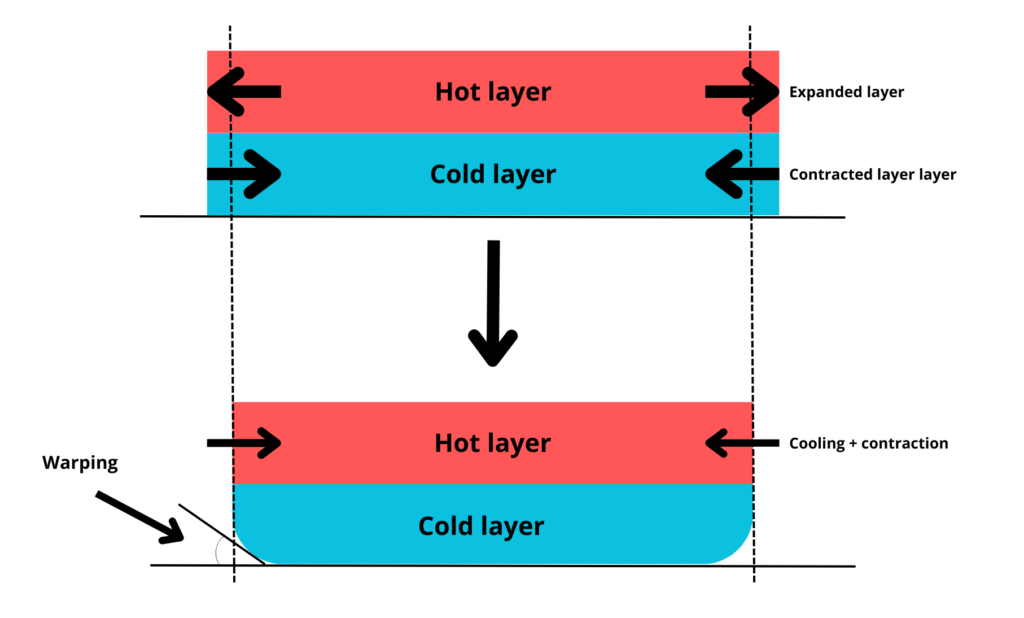

Reduce Stress Creation:

Internal stress during printing is a leading cause of warping. Stress occurs when polymer chains stretch while being extruded. They cool and contract, leading to warping.

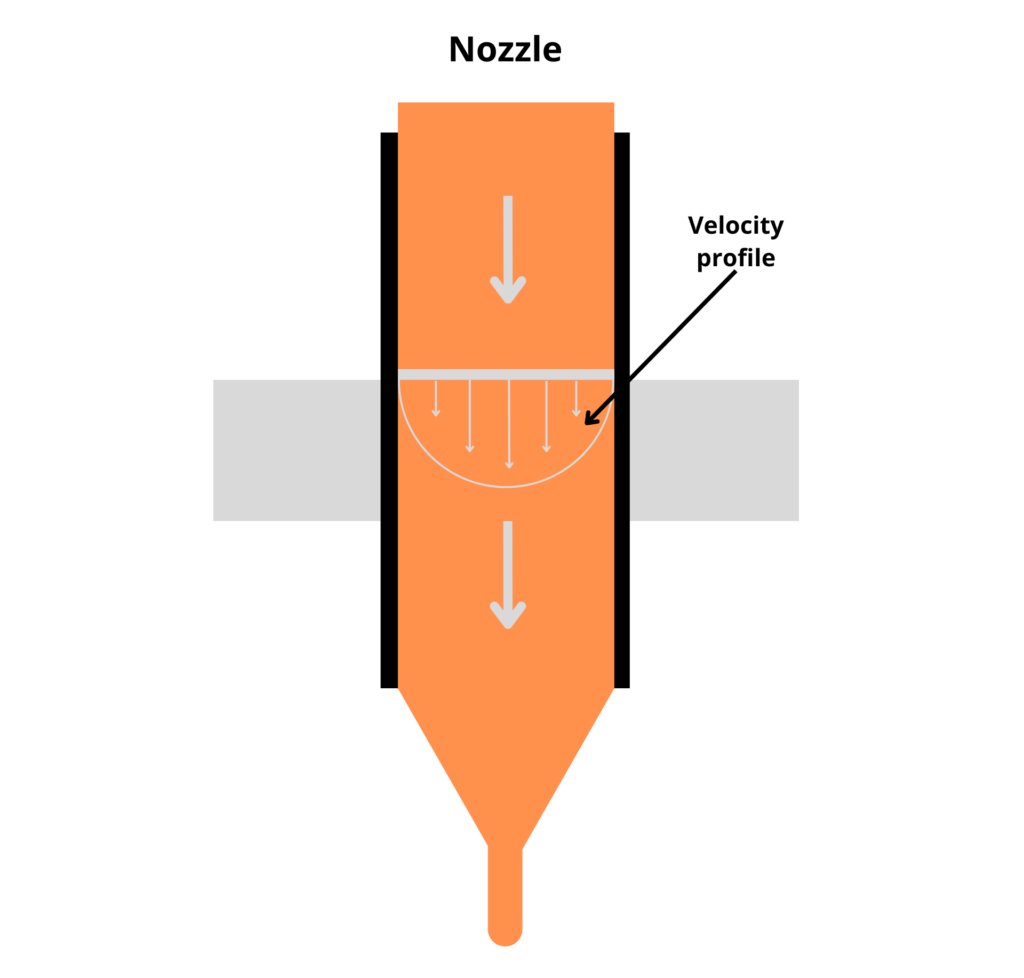

How to Reduce Stress:

- Flatten Velocity Profile: Slow down extrusion or increase nozzle size to reduce polymer stretching and stress.

- Increase Printing Temperature: Higher temperatures lower material viscosity, making extrusion smoother and reducing stress.

- Coat the Nozzle: Using a low-resistance coating on the nozzle’s surface helps ensure smooth material flow.

Manage Crystallization in Semi-Crystalline Polymers:

Semi-crystalline polymers, like Nylon, pose a unique challenge. These materials form small crystals when cooling, which causes shrinking and warping.

Ways to Control Crystallization:

- Control Cooling Rates: Slow cooling prevents rapid crystal formation, which reduces stress buildup in the layers.

- Optimize Print Settings: Heat the build plate appropriately and adjust cooling fan speed to slow down crystallization.

Conclusion:

Improving bed and layer adhesion, reducing internal stress, and managing crystallization can significantly reduce warping in your 3D prints. Apply these strategies to achieve better, more consistent results in your 3D printing projects.